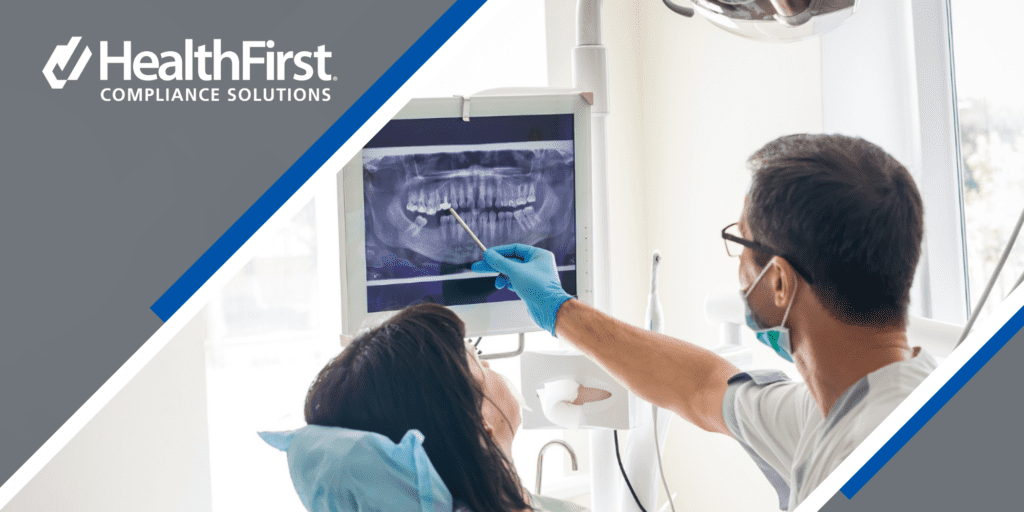

OSHA & HIPAA Compliance Training

Get expert guided online and mentored help to comply with your OSHA and HIPAA obligations: employee training, customized manuals, facility checklists and reports. Train, track and relax with support from our trusted OSHA and HIPAA training and compliance experts.

Available Courses

OSHA and HIPAA Training Features

OSHA and HIPAA standards are regulatory obligations all U.S. dental offices must meet for staff and patient safety. HealthFirst Compliance Solutions comprehensive OSHA and HIPAA packages give dental practices an unique and customized program to help you succeed. Let us partner with you and your Dental team to make compliance training easy and convenient while keeping your practice current with the latest regulations.

Guided training with

certified dental

professionals

- 1:1 training and support at your convenience

- Coaches help customize programs specific to your unique needs

- All coaches hold a certificate in dental infection prevention and control from OSAP and the DALE Foundation

Save time and money for single or multiple location practices

- Train as a team or individually from anywhere

- One platform easy to implement, maintain, and be consistent across your entire team

- Assign tasks, track progress and receive alerts

Stay current with the latest Federal and State regulations

- Receive timely updates on new or updated regulations

- Covers Federal and State OSHA and HIPAA regulations along with the latest CDC Guidelines

- Earn valuable CE credits

Now offering interactive compliance training for workplace safety. Courses available include Active Shooter Response Training and Sexual Harassment in the Workplace. Learn more below.

Testimonials

“Dental Enhancements provided our staff with very thorough and comprehensive updates for dental regulations, OSHA and HIPAA. The checklists provided helped us to get things up to regulation. When contacted for help, they respond promptly. Our staff feels it is the best OSHA education they have ever gotten.”

Aschim Dental

“Dental Enhancements products are great! Using the OSHA manual was easy and very helpful in getting the training required completed. Customer service has always been very helpful to assist when a problem or question arose. I would recommend their products to any dental office. Thank you for making our job easier!”

Dr. Steve Childress II, DDS

“Thank goodness for Dental Enhancement! Their streamlined, customizable OSHA manuals and forms really helped me during a recent local radiation department inspection. The coaches there are always helpful and gave me peace-of-mind when I needed it most, during the inspection process! They make the set-up and implementation process easy & approachable.”

Joleyn Carriveau, RDH, BS, PDHC

How Does Your Office Compliance Check Out?

Complete the form below or call us at (941) 587-2864 to get a 15-minute OSHA and HIPAA status review at no cost. Gain peace-of-mind and learn how to turn all current-day OSHA and HIPAA liabilities into assets for your busy dental office.

"*" indicates required fields